|

How M-System strives to meet delivery deadlines

We have been overcoming difficulties of parts procurement!

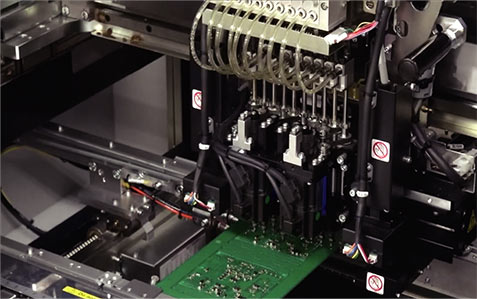

Chip mounter in the Kyoto Research Center and Factory,

supporting high-mix, low-volume production

Requirements to meet delivery deadlines:

1. Securing a parts stock with sufficient margin

2. Developing a strong relationship of trust with parts manufacturers

3. Establishing countermeasures to cope with difficulties of parts procurement caused by parts discontinuation or natural disasters

M-System has been taking necessary steps to ensure that all the three requirements are fulfilled. |

Video library

Video library